Precision down to the smallest detail

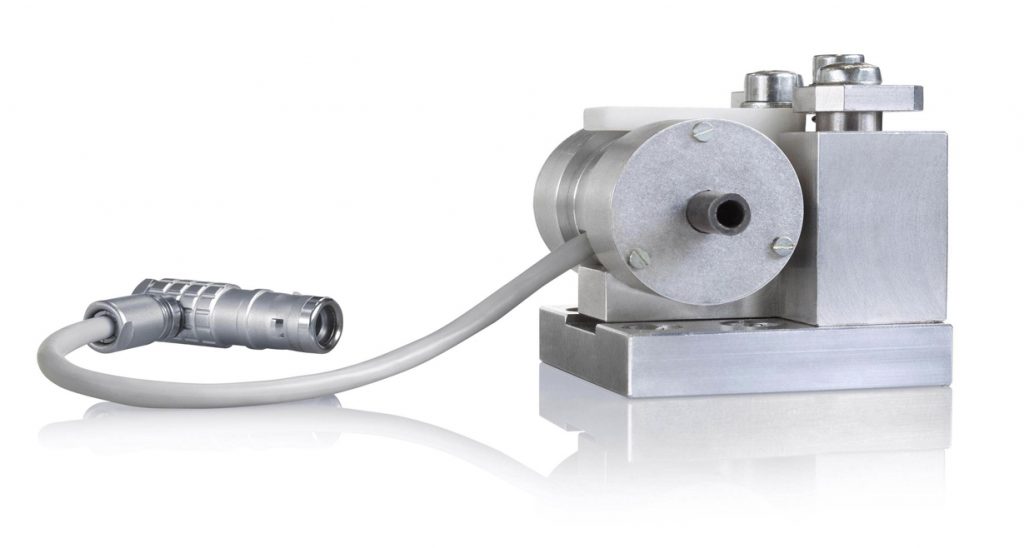

The DEFECTOMINI sensor system was developed for particularly fine wires and tubes with a diameter of 0.3 mm to 4 mm. It is used in medical technology, in coils for pacemakers, for instance, as well as in the chemical and electronics sectors. The permanent magnets inside the unit make it possible to test all types of metal, including ferrite materials. The system can be assembled directly in wire pullers thanks to its compact design.

Your advantages at a glance

- Localization of even the smallest surface defects using the eddy current method

- Increased defect detectability

- Permanent magnets make it possible to test even ferromagnetic materials

- Compact system for direct assembly in wire pullers

- Optional static holder for automatic test coil adjustment on the wire, thus automatic compensation for position changes

Technical Data

| Test coil diameters: | 0.3 mm – 4 mm |

| Excitation frequency range: | 10 kHz – 3 MHz |

| Maximum field strength on the test piece: | 200 kA/m |

| Test material: | all conductive materials |